THERMAL IMAGING

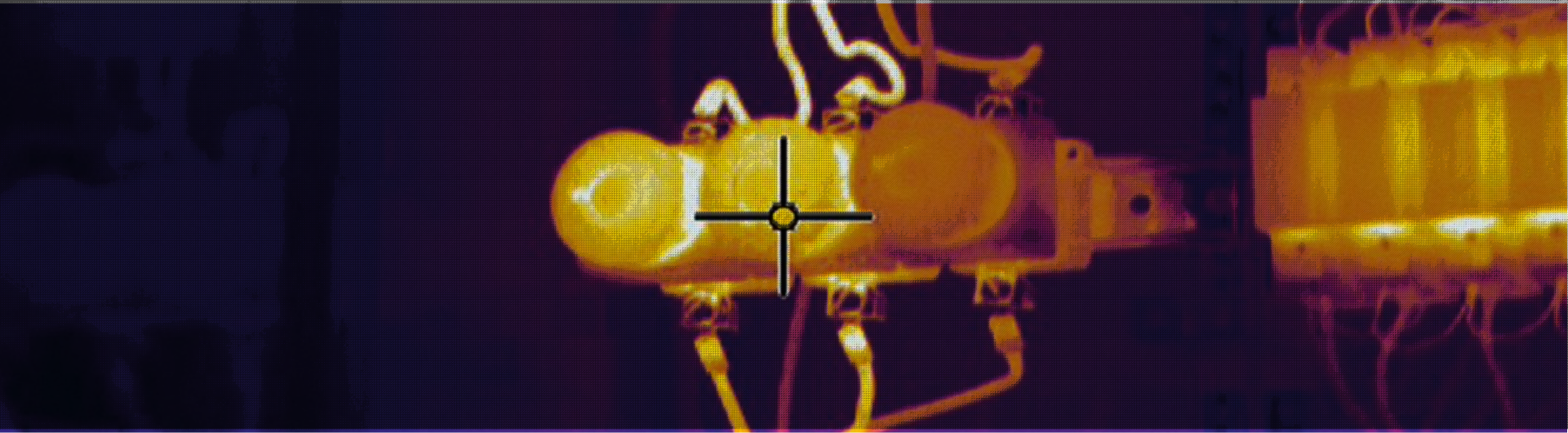

Thermal Imaging

See the problem before it becomes a problem

It’s the ultimate in preventative maintenance – using state-of-the-art thermal imaging technology to identify potential issues before they become a real problem. Armed with the Flir E53, Damian’s 12-monthly Infrared Thermal Inspection can help save you the time and money associated with an unscheduled outage or the failure of a component or system. It can also play a vital role in helping to ensure compliance with the annual insurance requirements of your operation.

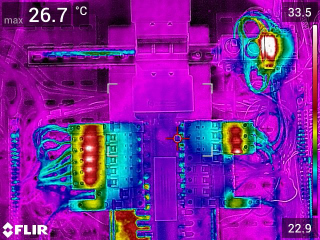

| Fault description | Nil |

| Fault rating | Low |

| Remedy | N/A |

| Thermographer | Damian Leahy |

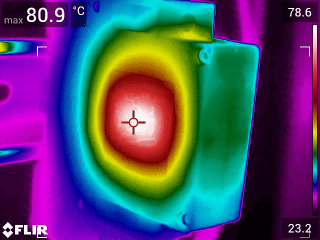

| Fault description | Control contactor over temperature |

| Fault rating | Medium |

| Remedy | Replace contactor |

| Thermographer | Damian Leahy |

| Damian Leahy | – Electrician – Thermographer (Level 1) – Nominee Supervisor in Fire Protection – Fire Protection Technician – Fire Safety Adviser |

Thermal imaging is ideal for:

- Switchboards

- Electrical components

- Electric motors

- Building inspections

- Water leaks

- Mechanical faults

- General fault finding

What you get:

- Comprehensive Thermography Report: prepared in accordance with the “Guideline for Infrared Inspections of Electrical and Mechanical Systems”, 1st Ed, Infraspection Institute (1993) – that meets ISO 18436-7

- Fault diagnosis, fault rating, and remedy at-a-glance

- On-the-spot rectification (if applicable)

- Updated asset record for your insurance files

- Peace of mind

“While modern electrical components are designed to ‘fail-safe’, older assets can unfortunately still run the risk of starting a fire. That’s why an annual thermal inspection shouldn’t just be about insurance compliance – it’s about protecting people and property, and keeping your business running”

Damian Leahy